Categories

Reaction Vessels

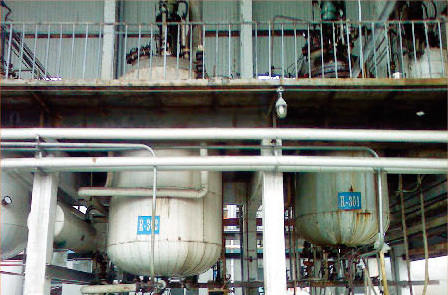

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction vessels are widely, used in industries of petroleum, chemistry, food, medicine, farm chemistry and scientific-research, to complete the chemistry processes like aggregation, condensation, vulcanization, alkylation, hydrogen sulfide, etc. The volume range is from 0.1~10m3; about the heating methods there are jacket or coil steam heating, electrical heating, oil heating and so on. The pressure, temperature, material, stirring device kinds, rotating speed, seal structure as well as heating methods can be determined according to material production requirements and users' needs. The primary products are stainless steel reaction kettle, semicircle jacket reaction kettle, multifunctional dispersion reaction kettle, fermenting tank, seed tank, depositing tank, extracting tank, concentration crystallizing boiler and so on.

Reaction vessels are widely, used in industries of petroleum, chemistry, food, medicine, farm chemistry and scientific-research, to complete the chemistry processes like aggregation, condensation, vulcanization, alkylation, hydrogen sulfide, etc. The volume range is from 0.1~10m3; about the heating methods there are jacket or coil steam heating, electrical heating, oil heating and so on. The pressure, temperature, material, stirring device kinds, rotating speed, seal structure as well as heating methods can be determined according to material production requirements and users' needs. The primary products are stainless steel reaction kettle, semicircle jacket reaction kettle, multifunctional dispersion reaction kettle, fermenting tank, seed tank, depositing tank, extracting tank, concentration crystallizing boiler and so on.

Reaction vessels are widely, used in industries of petroleum, chemistry, food, medicine, farm chemistry and scientific-research, to complete the chemistry processes like aggregation, condensation, vulcanization, alkylation, hydrogen sulfide, etc. The volume range is from 0.1~10m3; about the heating methods there are jacket or coil steam heating, electrical heating, oil heating and so on. The pressure, temperature, material, stirring device kinds, rotating speed, seal structure as well as heating methods can be determined according to material production requirements and users' needs. The primary products are stainless steel reaction kettle, semicircle jacket reaction kettle, multifunctional dispersion reaction kettle, fermenting tank, seed tank, depositing tank, extracting tank, concentration crystallizing boiler and so on.

Reaction vessels are widely, used in industries of petroleum, chemistry, food, medicine, farm chemistry and scientific-research, to complete the chemistry processes like aggregation, condensation, vulcanization, alkylation, hydrogen sulfide, etc. The volume range is from 0.1~10m3; about the heating methods there are jacket or coil steam heating, electrical heating, oil heating and so on. The pressure, temperature, material, stirring device kinds, rotating speed, seal structure as well as heating methods can be determined according to material production requirements and users' needs. The primary products are stainless steel reaction kettle, semicircle jacket reaction kettle, multifunctional dispersion reaction kettle, fermenting tank, seed tank, depositing tank, extracting tank, concentration crystallizing boiler and so on.

Reaction vessels are widely, used in industries of petroleum, chemistry, food, medicine, farm chemistry and scientific-research, to complete the chemistry processes like aggregation, condensation, vulcanization, alkylation, hydrogen sulfide, etc. The volume range is from 0.1~10m3; about the heating methods there are jacket or coil steam heating, electrical heating, oil heating and so on. The pressure, temperature, material, stirring device kinds, rotating speed, seal structure as well as heating methods can be determined according to material production requirements and users' needs. The primary products are stainless steel reaction kettle, semicircle jacket reaction kettle, multifunctional dispersion reaction kettle, fermenting tank, seed tank, depositing tank, extracting tank, concentration crystallizing boiler and so on.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.