Categories

Product

Towers are primarily applied as material transfer equipments between gas phase and liquid phase or liquid phase and liquid phase. The towers can be classified into two kinds according to its structure, one is plate tower and the other is packing tower. The inside of plate towers is loaded stuffing with certain height, the liquid flows downwards along the stuffing, the gas contacts liquid film upwards in reverse current, and then to carry out material transfer. It's often used in operation of distillation, water absorption and extraction. The important products of towers are fractionation tower, rectifying tower, distillation tower, desulfuration tower, regeneration tower, saturation tower, hot water tower, water scrubbing tower, stripping tower, degassing tower, synthesizing tower and so on

The main products have fixed tube sheet, floating-head type, stuffing box type, kettle type, double tube sheet type, fin type and screw type heat exchangers, condensers, they are used for materials heating and cooling processes of petroleum, chemistry, medicine and architecture industries.

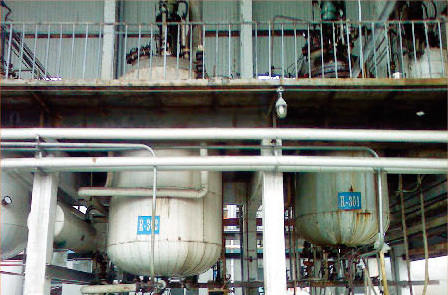

Storage tanks has series of normal pressure and pressure vessels, whose main products are liquefied petroleum gas tank, liquid ammonia tank, compressed air tank, nitrogen tank, large tanks as well as vessels used for materials storage in all kinds of technologies.

Storage tanks has series of normal pressure and pressure vessels, whose main products are liquefied petroleum gas tank, liquid ammonia tank, compressed air tank, nitrogen tank, large tanks as well as vessels used for materials storage in all kinds of technologies.

Storage tanks has series of normal pressure and pressure vessels, whose main products are liquefied petroleum gas tank, liquid ammonia tank, compressed air tank, nitrogen tank, large tanks as well as vessels used for materials storage in all kinds of technologies.

Storage tanks has series of normal pressure and pressure vessels, whose main products are liquefied petroleum gas tank, liquid ammonia tank, compressed air tank, nitrogen tank, large tanks as well as vessels used for materials storage in all kinds of technologies.

Storage tanks has series of normal pressure and pressure vessels, whose main products are liquefied petroleum gas tank, liquid ammonia tank, compressed air tank, nitrogen tank, large tanks as well as vessels used for materials storage in all kinds of technologies.

Storage tanks has series of normal pressure and pressure vessels, whose main products are liquefied petroleum gas tank, liquid ammonia tank, compressed air tank, nitrogen tank, large tanks as well as vessels used for materials storage in all kinds of technologies.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction containers are widely used in petroleum, chemical, food, medicine, pesticide, scientific research and other industries, and are used to complete polymerization, condensation, sulfide alkylation, hydrogenation and other chemical processes. The volume varies in size, heating methods include jacket or coil steam heating, electric heating, oil heating, etc. According to the material production requirements and user needs to determine the pressure, temperature, material, mixing device type, rotation speed, sealing structure, heating mode to design and manufacture. The main products are stainless steel reaction kettle, semicircular tube jacket reaction kettle, multifunctional dispersive reaction kettle, ferment tank, seed tank, precipitation tank, extraction tank, concentrated crystallization pot, etc.

Reaction vessels are widely, used in industries of petroleum, chemistry, food, medicine, farm chemistry and scientific-research, to complete the chemistry processes like aggregation, condensation, vulcanization, alkylation, hydrogen sulfide, etc. The volume range is from 0.1~10m3; about the heating methods there are jacket or coil steam heating, electrical heating, oil heating and so on. The pressure, temperature, material, stirring device kinds, rotating speed, seal structure as well as heating methods can be determined according to material production requirements and users' needs. The primary products are stainless steel reaction kettle, semicircle jacket reaction kettle, multifunctional dispersion reaction kettle, fermenting tank, seed tank, depositing tank, extracting tank, concentration crystallizing boiler and so on.

Reaction vessels are widely, used in industries of petroleum, chemistry, food, medicine, farm chemistry and scientific-research, to complete the chemistry processes like aggregation, condensation, vulcanization, alkylation, hydrogen sulfide, etc. The volume range is from 0.1~10m3; about the heating methods there are jacket or coil steam heating, electrical heating, oil heating and so on. The pressure, temperature, material, stirring device kinds, rotating speed, seal structure as well as heating methods can be determined according to material production requirements and users' needs. The primary products are stainless steel reaction kettle, semicircle jacket reaction kettle, multifunctional dispersion reaction kettle, fermenting tank, seed tank, depositing tank, extracting tank, concentration crystallizing boiler and so on.